Quick summary: Stainless steel is one of the most reliable heat shield materials for exhaust heat shielding because it resists corrosion, handles vibration, and protects against radiant heat when designed correctly. This guide explains stainless steel heat shield material types, selection rules, and installation tips used by engineers and builders.

Why stainless steel | Material types | Selection rules | Installation tips | Common mistakes | FAQ

Exhaust systems combine high surface temperatures, vibration, thermal cycling, water spray, salt exposure, and tight packaging. A practical stainless steel heat shield material must stay stable under these conditions while maintaining a protective air gap. Stainless steel is widely used for heat shielding because it offers:

In real builds, the most effective exhaust heat shield solutions are usually multilayer systems: a stainless steel outer layer + an insulation layer + a controlled air gap. For high heat sources, reducing heat at the source can be even more effective. See our exhaust insulation solutions for turbo and pipe surface temperature control.

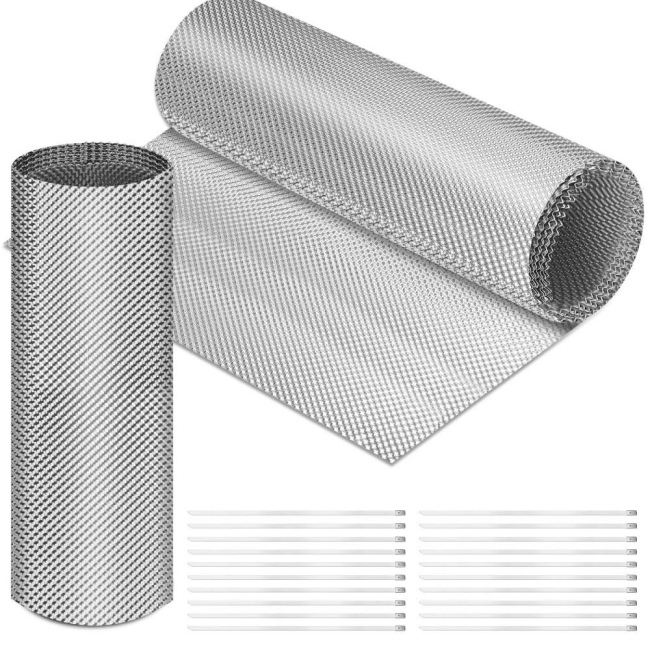

Embossed or dimpled stainless designs help maintain micro-spacing and improve stiffness, which is valuable for underbody vibration. They are often used as an outer “armor” layer or as part of a composite barrier. This style is common when you need a durable heat shielding layer that holds shape and protects the insulation beneath it.

Stamped shields are shaped to fit vehicle geometry and typically mount with brackets, bolts, or clips. When designed correctly, they preserve an air gap and protect nearby components from radiant heat. If you need custom cut shapes or formed parts, review custom capabilities.

For higher heat loads, stainless is often combined with insulation (fiberglass/silica/aerogel composites, depending on the design requirement). The stainless layer improves durability and handling, while the insulation reduces heat transfer. For severe exhaust zones, pair shielding with source insulation such as exhaust insulation solutions.

Use these rules to select the right stainless steel heat shield material for your application:

A well-maintained air gap is often the difference between “some improvement” and “significant improvement.” Embossed/dimpled stainless can help preserve spacing where packaging is tight.

Underbody heat shields fail when they lose shape, loosen, or rub through. Choose a stainless construction and mounting method that stays secure. For fastening and edge control, heat shield tapes and barriers can support localized sealing and protection depending on temperature zone.

Heat shielding protects adjacent parts; source insulation reduces temperature at the origin. For turbo, downpipe, or pipe surface temperature control, start with exhaust insulation solutions. Then add stainless shielding where radiant heat must be blocked from sensitive components.

Yes. Stainless steel is durable in underbody environments and resists corrosion and vibration. The best results come from designs that preserve an air gap and use multilayer constructions when heat loads are high.

Embossing improves stiffness and helps maintain spacing. This supports more stable heat shielding under vibration and thermal cycling, especially when packaging is tight.

Heat shielding protects nearby parts from radiant heat. Exhaust insulation reduces heat at the source. In severe zones, combining both is the most reliable approach: use exhaust insulation solutions and then add stainless shielding where necessary.

If hoses or wiring route close to the exhaust, add dedicated thermal protection such as fire sleeve protection. For localized edge protection, use suitable heat shield tapes and barriers where applicable.

Send your application details (heat source temperature, clearance, mounting method, and target coverage area). We will recommend a practical exhaust heat shielding structure and provide supporting technical documents.

العلامات :